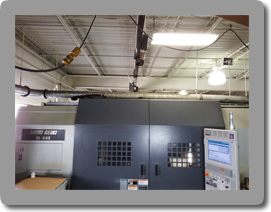

K&G Machine Co. has made a commitment to provide comprehensive services to our customers. Our CNC Machining capabilities allow us to provide complex, close tolerance parts at economical prices. We are committed to continually update and broaden our machine tool technology. Use of DNC system offers short lead times and consistent repeats.

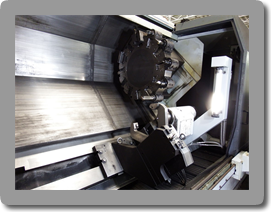

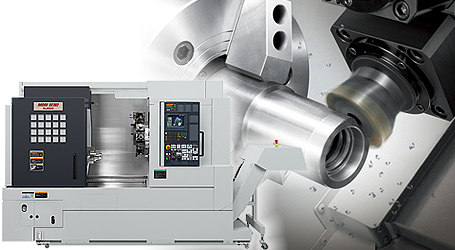

Mori Seiki SL 403 Lathes

A machine that maximizes and stabilizes speed and high precision.

Max. turning diameter

25.6 in.

Max. workpiece length with tailstock (workable)

85 in.

Max. chuck diameter

21 in.

Max. rotational speed of the spindle

2,400 rpm

Output (100% power-on time)

40.2 hp.

Control & software

MAPPS FANUC

High-Performance Operating System: MAPPS IV

Interface that makes operation simple and easy

MAPPS IV by DMG MORI

MAPPS IV is designed to be easy for operators to use, with a large display, easy-to-use PC-type keyboard, and vertical soft-keys which provide quick access to your desired screen. MAPPS IV has many user friendly features which allow more intuitive operation and enhanced maintenance functions.

Outstanding operability thanks to upgraded hardware

Enhanced functionality by using CAM software (option)

New functions for easier setup and maintenance

Spindle/Superior rigidity

Oil chiller included as standard equipment (C-type)

The spindle drive utilizes a high-output, high-torque AC spindle motor that can handle heavy and/or continuous cutting of a variety of workpieces.

Single body bed and legs for high twisting and bending rigidity.

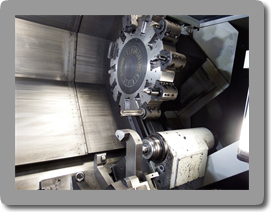

Turret / Feed

Turret indexing time 0.4 sec. (1-station)

Rapid traverse rate

X-axis: 787.4 ipm

Z-axis: 944.9 ipm

Ideal for shaft workpieces

Max. turning diameter: 24.4 in.<B, C>, 25.5 in. <BMC, CMC>

Max. turning length : 37.7 in. <SL-403B/800>, 84.9 in. <SL-403B/2000>

Tailstock travel: 33.5 in.<800 type>, 78.7 in.<2,000 type>

NL3000

Modular Design Turning Center configured with or without milling function, and with optional off-center Y-axis milling capability

Machine Style(s): Bar, Chucker, Universal

Spindle Direction: Horizontal

Operation Type: CNC

CNC Type: Standard: Mitsubishi MSX-850 III

HEADSTOCK

Chuck Size (in.) Std: 12.000 Max. Swing: 39.200

Turning Diameter Max: 16.500

Turning Length (in.) Max: 28.000 Opt Max: 122.900

Bar Capacity (in.) Std: 3.500

Tailstock: Standard (in.) Quill Dia: 4.300 Quill Center: MT#5 Body Travel: 28.900 Body Travel Opt: 50.600

SINGLE SPINDLE

# of Main Spindles: 1

Main Spindle: rpm: 3000 HP: 40.00

Nose: A2-8 Bore: 3.500

# Speed Ranges: 1

TOOLING

Primary Tool Carrier: Turret

Max Tools Turning: 10 Rotary: 10

Tool Shank Size (in.): Square: 1.000 Round: 2.000 Rotary: 1.000

Rotary Tool Spindle: rpm: 6,000 Power: 7.50 hp

# of Simultaneous Cutting Tools: 1

Secondary Mill/Drill Function On-Center: Optional With 'C' Axis: Optional

Off-Center: Optional With 'Y' Axis: Optional

AXES AND TRAVELS

Number of Axes: Standard: 2 Optional: 3, 4

Travel Max Feed Rapid Rate

C1 Opt. 360.000 deg 300 rpm

X1 Std. 11.000 in. 1,181 ipm

Y1 Opt. 4.700 in. 394 ipm

Z1 Std. 32.300 in. Opt. 124.80 in. 1,181 ipm

CNC Lathes

Quality Control

© 2018 http://www.kandgmachine.com. All Rights Reserved.